High Speed Tubular Bowl Super Centrifuges

With its ever increasing ease of use, the Pennwalt Super Centrifuge takes separation efficiency to unprecedented levels.

Relied upon by several global biotechnology and biopharmaceutical companies worldwide, Pennwalt’s tubular bowl Super Centrifuge operates at 20000G and 17000 rpm. The time tested Sharples design continues to please customers. The versatility of options allows Pennwalt to build centrifuges which can cater to each client’s unique needs.

Applications for our Super Centrifuge are countless. Some prominent applications include virus recovery, sedimentation of bacteria, blood plasma production and fractionation, and preparation of serums and vaccines. There are other applications, and we welcome enquiries for the same.

How Super Centrifuge works:

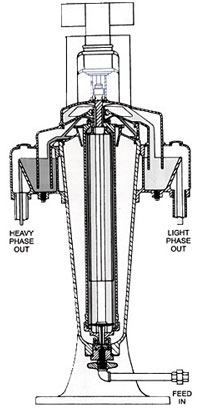

This sectional view of a Super-Centrifuge shows the application of centrifugal force to a mixture of two immiscible liquids containing some suspended solids.

The mixture continuously enters the Super-Centrifuge through an inlet feed nozzle at the base of the machine, into the hollow cylindrical rotor. Rotors have been designed and engineered to rotate at 17000 r.p.m. and generate centrifugal force of upto 20000 times the force of gravity.

This force separates the two liquids according to their specific gravities into concentric cylindrical layers, and the solids are deposited inside the rotating bowl against the rotor wall.

The separated liquids are continuously displaced upwards by the incoming mixture and continuously discharged through their respective outlet ports at the top of the rotor. The layer of accumulated solids that builds up on the inner diameter of the rotor wall is cleaned out batch-wise for which the super-centrifuge is shut down when it is filled up to the rotating bowl’s limiting solids holding capacity and the rotating bowl is removed for cleaning.

There are, however, many applications where only the removal of suspended solids from a single liquid is required. Super centrifuges for such applications are called Clarifiers and are often provided with only one set of discharge ports. Mylar Liners are optionally supplied and can be placed on the inner diameter of the bowl for ease of removal of insoluble solids deposited on the inner diameter of the bowl.

The fields of application of the Super-Centrifuge are almost unlimited. The number of processes which involve a liquid / liquid, liquid / liquid / solid, or liquid / solid separational steps are too numerous to be described here. A few of the better known ones are mentioned briefly below:

General Applications here includes:

Clarifications of

- Dry Cleaner’s Spirit

- Animal Fats Dehydration

- Water Gas Tar

- Fish Oils

- Ball Pen Ink

- Wool Grease

- Printing Ink, etc.

Chemicals and Pharmaceuticals Applications here include:

- Clarification of caustic in Rayon Industry (Steep press liquor)

- Soda solution

- Gum clarification

- Blood fractionation

- Virus recovery

Food Manufacture

- Cider and wine clarification

- Soup clarification

- Fat clarification

- Fruit juice clarification

- Cocoa butter clarification

- Chocolate scrap recovery

- Chewing Gum

- Cherry Syrup

Paint and Varnish

- Removal of oversize pigments from paints and lacquers.

- Clarification of Varnish

- Removal waste ink from newspaper

- Purification of molten wax:

- Removal of ash & water from molten wax in investment casting industries.

Materials of Construction: Numerous options are available as per application specific customer requirements. If required all parts in contact with process material can be of stainless steel.

MINERAL OIL PURIFICATION

A Super-Centrifuge with accessories such as feed and discharge pumps, thermostatically controlled heater, in stationary or portable execution, is a very useful unit for a modern factory (Enblock Unit) for:

Oil Purification

- Diesel fuel oil

- Diesel lubricating oil

- Heavy fuel oil

- Turbine lubricating oil

For Power Stations

Units with stainless steel bowl, special safety features such as anti-flood device and indirect heater are recommended for modern thermal power stations for purification of turbine lubricating oils.

In steel mills and engineering works for the purification of:

- Rolling mill oil

- Engine test bed oil

- Cutting and hardening oils

- Grinding and drawing oils

- Hydraulic oils

For Bio-diesel Production:

The model AS-16 and model AS-26 high-G Tubular Bowl Super Centrifuge are used for the following separations in Bio-diesel Production to obtain the final purity of Bio diesel to international standards eg. ASTMD-6751:

- Machine can be operated at high G forces up to 20000 x G

- Centrifuge enclosure can be designed for N2-blanketting & minimum solvent vapors loss wherever excess methanol is present.

Features :

- Separation of Biodiesel from Glycerol+Methanol mixture after trans-esterification.

- Separation of Biodiesel from Wash-Water in the subsequent bio-diesel washing steps.

The machines can be supplied whenever required, with special features for minimizing solvent loss and for mitigating solvent hazards.

For Human Blood Plasma Fractionation:

Both the Model AS16 and AS26 Super-centrifuge models are available with electro-polished Vaportite / Vapourseal covers which are ideally suited for fractionation of Blood Plasma based on variations of Cohn’s Process wherein the slightest contamination means the loss of a complete batch. Furthermore, the three piece frame comprising the pedestal, barrel and swivel head is painted in white to a pharmaceutical finish. Furthermore, the stainless steel contact parts such as the bowl interior in Stainless Steel or equivalent material, the stainless steel covers and certain stainless steel drag components are polished to high sanitary standards to ensure functionally satisfactory performance. In addition, the barrel is preferably jacketted for cooling media circulation and the pulley assembly is fitted with grease packed bearings to ensure a clean, reliable and effective performance. Flame Proof Electrical Drive Motor and Flame Push Start-Stop Push Button station can be provided for safety during operation. Features can also be provided for Inert (N2) Gas purging wherever required for safety.

For Pharma & Bio-technology Applications:

Many hazards with industrial bio-processing with real or perceived risks such as highly pathogenic bacteria, viruses, etc. need to be processed using Model AS-16 and AS-26 high-G Tubular Bowl Super Centrifuges which are built with Sanitary Design Features for separation of Biological material, and are featured for Biotechnology application requiring BL-1-LS containment of biohazards. The super centrifuges can be also featured for BL-2-LS containment of biohazards, if necessary. To ensure safe processing, a risk assessment, corresponding bio-hazard containment and bio-safety issues must be examined by bio-process engineers of the end-use customer. The super centrifuges are featured and designed with the relevant appropriate containment for Sterilisation-in-Place which should be validated by the end-user’s bio-process engineers and operators.

Features:

- Complies with cGMP standards.

- All stainless steel wetted parts are electro-polished to Ra < 0.5 microns.

- Inbuilt centripetal pump is provided for foam and aerosol control.

- Variable speed Drive achieves operations between 7500 x G to 17000 x G or 20000 x G depending upon the model of Super Centrifuges.

- Sterlization-in-place (SIP) feature is provided with special vaportite covers designed to accept clean saturated steam at 1.0 barG and 1210C, and incorporates a Safety Rupture Disc.

- Clean-in-Place (CIP) feature is provided.

- A dedicated Control Panel is provided with status indicating illuminators, ON-OFF Push Buttons, and Auto-Manual Sequence Control of CIP and SIP operations.

- The Barrel, Pedestal and Drive plate can also be optionally made of stainless steel, based on application specific customer requirements.

Applications:

- High Value Pharmaceutical Products Recovery with BL-1-LS Containment Level such as during Separation Of E-Coli Whole Cells & E-Coli Lysed Cells to cGMP Standards.

- Vaccine membrane fragment classification.

- Vaccine Conjugated Protein Separation

- Fractionation Of Human Blood Plasma Into Its Protein Fractions Viz: Fibrinogen, Gamma Globulin, Immunoglobulin, Thrombin, Albumin on the basis of Dr. Cohn’s Procedure variations.

- Virus Particles Separation (0.06µ)

- Harvesting Biomass

- Mammalian Cell Debris Separation

- Clarifying Process Liquids

- Cryoprecipitate Separation

- Animal Blood Processing

- Yeast Cell Debris

- Stroma (cell wall fragment)

- rDNA Injectables

- Protein precipitate (PEG) Separation

- Protein precipitate (NH4SO4) Separation

- Bio-remediation processes

The special features of Pennwalt Tubular Bowl Supercentrifuge built for pharmaceutical and biotechnology applications are as given below:

- Stainless steel pedestal and barrel: For centrifuges used in pharmaceutical and biotechnology applications, we presently supply centrifuges with SS304 pedestal and SS316 barrel.

- Jacketed barrel: Pennwalt has developed the jacketed barrel feature in lieu of the old cooling coils. Jacketed Barrel is provided in SS316 polished to a sanitary finish for cooling media circulation. With adequate brine flow at suitable temperature, it can minimize the temperature rise of feed material to prevent degradation of the products.

- Higher bowl speed and centrifugal force: Pennwalt AS26V model tubular bowl centrifuge can be operated at a maximum bowl speed of 17000 rpm corresponding to a centrifugal force of 20000 x G. This results in better separation of even the tiniest solid particles.

- Tiltable barrel: The AS26V centrifuge can be built in two configurations, namely the pivoted drive plate and the tiltable barrel.

In the pivoted drive plate variant, after uncoupling the bowl, the drive plate is swung circumferentially to facilitate vertical lifting of the bowl using a chain pulley block or other lifting device.

In the tiltable barrel variant, the barrel can be tilted to a horizontal position and the bowl can be slid on to a bowl cart and carried to the bowl cleaning section. This does not involve lifting of bowl and it is found to be very useful in hygienic applications where the headroom available is small.

- Stainless steel trolley: The centrifuge can be mounted on a stainless steel trolley for easy maneuverability of the machine.

- Self-sealing bowl bottom: The bowl bottom could be either having a three leg post or self-sealing type, which is a recently upgraded feature.

The self-sealing bowl bottom arrangement allows the bowl to be fed continuously during operation and to retain its contents at the end of a batch run, when the rotation is stopped and the bowl comes to a stand-still

Such a facility is necessary in applications, for instance where the concentrate virus or vaccine solids are a valuable product which is accumulated in the bowl, and where this must be kept free from contamination as might occur if drained across the drag or frame surface, or across a mild steel bowl bottom boss sleeve.

- Further we could also offer you optional items like the bowl washing tank in SS304 for cleaning the bowl after removal of the separated solids before assembling it to the centrifuge.

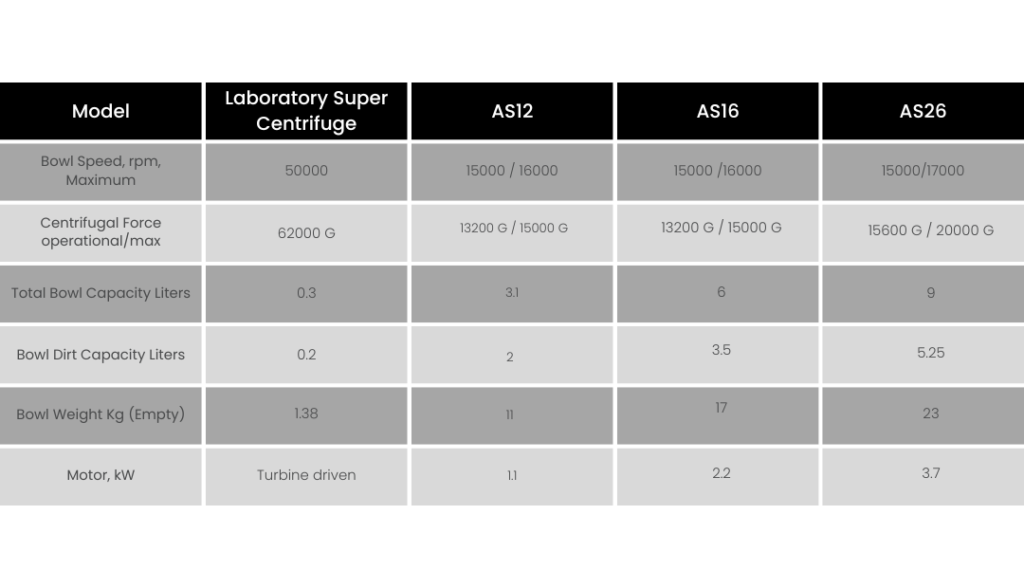

Specifications:

Model: Bowl Speed, rpm Operational/max

Laboratory Super Centrifuge: 23000 / 25500

AS12: 15000 / 17000

AS16: 15000 /17000

AS26: 115000/17000

Model: Centrifugal Force operational/max

Laboratory Super Centrifuge:13150G / 16200 G

AS12: 13200 G / 17000 G

AS16:13200 G / 17000 G

AS26: 156000G/20000G

Model: Total Bowl Capacity Liters

Laboratory Super Centrifuge: 0.3

AS12: 3.1

AS16: 6

AS26: 9

Model: Bowl Dirt Capacity Liters

Laboratory Super Centrifuge: 0.2

AS12: 2

AS16: 3.5

AS26: 5.25

Model: Bowl Weight Kg (Empty)

Laboratory Super Centrifuge: 1.38

AS12: 11

AS16: 17

AS26: 25

Model: Motor, KW

Laboratory Super Centrifuge: 0.19

AS12: 1.1

AS16: 2.2

AS26: 3.7