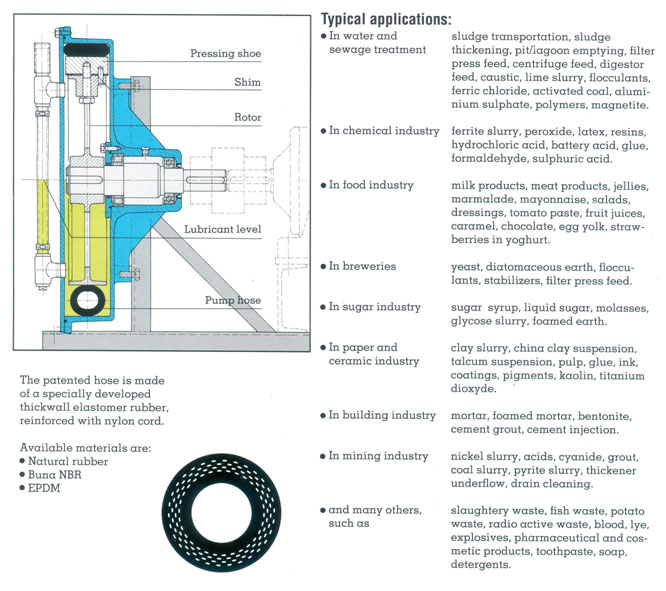

A composite, reinforced hose is enclosed within a casing that is flanged at both ends. The flanges are connected to the suction and discharge lines of the system. Within the casing is a rotor with two pressing shoes at opposite points about its centre line and mounted on a shaft with two bearings. As the rotor rotates, the hose is totally compressed by the shoes and the product within the hose is pushed forward. At the front of the pump is a removable cover with inspection window and level indicator. The pump casing is filled to approx. half way level with a specially compounded (food grade) lubricant which functions as a coolant as well. The patented hose is constructed from rubber laminations with an internal reinforcement which ensures that compression forces are evenly applied across its full width.

- Highly suitable for: – abrasive products.

- Corrosive Products

- Shear sensitive products

- Viscous products

- High density products

- Metering purposes (repeatable accuracy ± 1 %)

- Vacuum situations

- Use in explosive environments

- Self priming to 95% vacuum

- Can run dry. i.e. can run without fluid continuously.

- Reversible rotation.

- Replacement of hose without dismantling pump.

- Easy to clean: smooth liquid passage without valves. cavities or glands.

- No metal to metal contact.

- Product pumped does not contact mechanical parts or seals.

- Heavy duty bearings. greased for life.

- Designed and built for high discharge pressures.

- Low noise level.

- 100% positive flow (no slip).

- Only one wearing part: the pump hose.

- Easy maintenance. low cost. short down time.

- Permanent lubrication of pump hose with specially com¬pounded food grade lubricant.

- Any drive system possible.

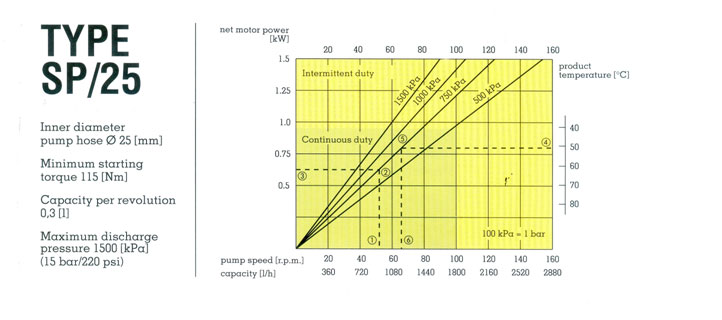

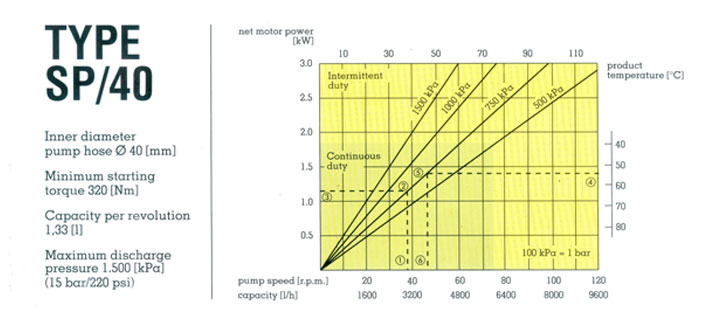

Note : Bigger model can be supplied on request.