SPS Vibroscreens (Vibrating, Classifying & Clarifying Screens)

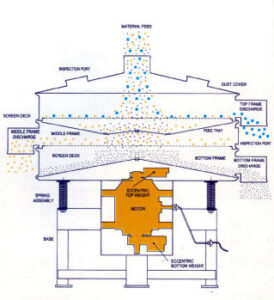

Pennwalt manufactures circular gyratory Vibroscreens which can be fitted with upto seven screens and continuously produces different grades of material according to the mesh sizes of screens fitted.

Vibroscreens can be used either for wet solid-liquid separation or for dry solids classification.

The Vibroscreen produces three-component multi-plane mechanical vibrations. It can handle particles ranging from 10 mm to 400 mesh in size. It gives very high capacity per square feet of screening area & consumes minimum energy. The generation of vibrations is through a special vibrating motor with a double extended shaft, fitted at both ends with eccentric weights.

The whole base-unit drive assembly is mounted on a circular base with rugged springs which allows the unit to vibrate freely, and comprises base and a motor table, support springs and spring mounts, top and bottom eccentric weights, a lead scale indicator, and a heavy duty motor for operation on three phase power supply.

The springs prevent transmitted vibration reaching the floor area on which the machine stands. The screen deck assemblies and spacing frames are mounted on top of the base unit and are connected together by stainless steel quick release circlular clamps. Screen deck assemblies can be mounted one on top of the other within the Vibroscreen assembly. The Vibroscreen is suitable for all types of screening operations within these four broad categories.

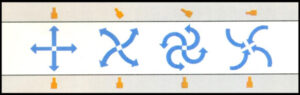

Highest screening efficiency is achieved by controlling the patterns of movement of solids on the screen surface. Control is achieved by varying the position of the bottom eccentric weight as shown in the diagram.

The special vibrating motor is manufactured by Pennwalt after long developmental work and the motor is very robust and reliable in nature.

Dry Screening /Classification

This involves separation of materials into different fractions on the basis of their particle size and openings of the screens fitted. Typical applications include screening of tea leaves, milk powder and detergent powder.

Solid-Liquid-Separation

This involves dewatering of solids and clarification of liquids.

Typical applications include screening of milk of lime, raw juice in sugar mills and Kaolin clay slurry.

Vibroscreen Operation:

The material is fed on to the centre of the top screen and the oversize material is moved by the multi-plane motion to the periphery of the screen to be discharged through a tangential outlet. The undersize particles and / or liquids pass through the screen to produce fine sized fractions or clarified liquid.

Top Eccentric Mass If the mass of the top eccentric is increased, this will increase the horizontal throw on the screen and will cause the oversize material to discharge at a fast rate.

Bottom Eccentric Mass An increase in the bottom eccentric mass will increase the vertical component of the motion. In the case where ‘near size’ blinding of the screen is a possibility, it is desirable to promote maximum vertical component of the motion in order to dislodge particles which may be held (pegged) in the interstices of the screen.

Bottom Eccentric Lead Angle:

The tangential component of the motion imparted to the solid on the screen is controlled by the angular position of the top and bottom eccentric weights. The screening pattern can therefore be controlled by altering the angle of the eccentrics and some general examples of the type of control are shown in the diagram below.

Note : Ball tray with rubber balls are specified where there is a problem of near size blinding. The balls hold the screens open by their repeated impact on the underside of the screen. However, where blinding is caused by fibres stapling around the screen wires, cylindrical kleen rings of PVC/HDPE are used, operating with a close fit on the screen for effectively anti-blinding the screen by shearing the fibres and prevent a build-up.

High Capacity, Minimum Space

By varying the angular displacement of the bottom eccentric weight, the screening pattern can be optimised for each job, thus giving a high capacity per square foot of screen surface.

Adaptability

Discharge ports can be rotated to meet layout requirements and individual frames between screen decks can be tailored to suit the needs of that fraction.

No Transmitted Vibration

Motion is transmitted through the screening assembly and vibration is completely absent from the screen base. No special foundations are required and many screens are operating suspended from ceiling hangers. By the same token, the machine can be made portable and its operation is silent.

Long Screen Life

Pennwalt have developed a special screen holding device and a taut screen cloth is achieved on assembly. The cloth does not flex and moves rigidly with the screen assembly.

Minimum Screen Blinding

The vertical component of the vibration given by the bottom eccentric weight ensures that blinding of the screen by particles close in size to the screen cloth aperture is minimised. Ball trays / Kleen Rings can be added if necessary to alleviate screen blinding.

Low Operating Costs

The Vibroscreen uses only low power motors, since all their energy is used to create screen motion and none is wasted in vibrating a massive frame and foundation.