Super-D-Canter

Pennwalt Super-D-Canter Centrifuge

The Pennwalt Super-D-Canter Centrifuge is a specially developed continuous Solid-Bowl Horizontal Scroll Discharge centrifuge for effective separation of slurries into clarified liquid and dewatered cake solid phases, with the application of centrifugal sedimentation principle.

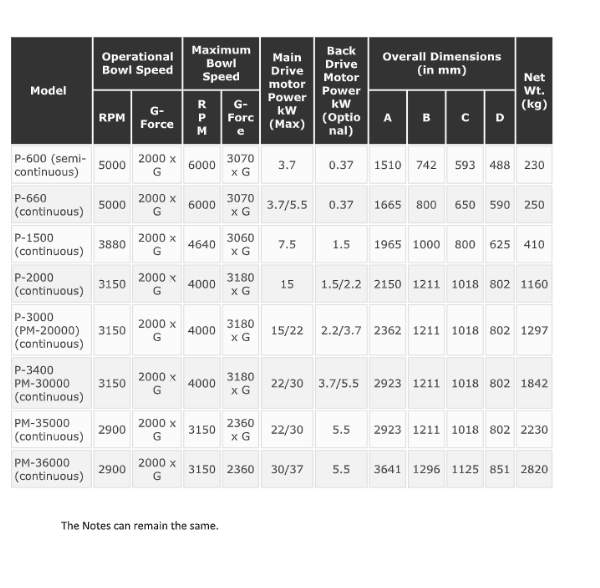

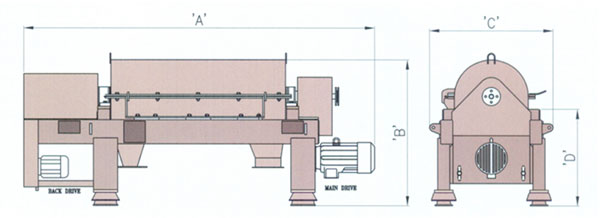

Pennwalt Private Ltd. are manufacturers of Decanter Centrifuge Models P600, P660, P1500, P2000, P3000/PM20000, P3400/PM30000, PM35000 and PM36000 based on the technology acquired from Sharples Stokes Division of Pennwalt Corporation-USA.

Pennwalt also supply spare parts manufactured to international standards that are interchangeable on each of the above models of the Decanter Centrifuge.

Continuous Solid Liquid Seperation

Solids are continuously separated from the liquid phase by the application of centrifugal force ranging up to 3000 times the force of gravity, efficiently and economically. A characteristic feature of the Pennwalt Super-D-Canter Centrifuge is the cylindro-conical bowl containing within a helical/quasi-axial screw conveyor of matching profile that rotates in the same direction but at a slightly slower speed with respect to the bowl.

Extremely Flexible Separations Tool

- Handles slurries with a wide range of solid particle sizes from 5.0 mm to a few microns

- Handles slurries with insoluble solids content from as low as 0.5%w/v to as high as 55%w/v.

Wide ranging, process specific applications of Pennwalt Super-D-Canter centifuge encompass

- Clarification of liquids.

- Dewatering or de-liquoring of insoluble suspended solids.

- Thickening or concentration of insoluble suspended solids.

- Classification of insoluble solids suspended in liquid.

For a detailed list of applications where the Pennwalt Super-D-Canter Centrifuge has been successfully used click here

Economical Operation

Pennwalt Super-D-Canter Centrifuge has polymiser features, wherein the feed zone & conveyor flights are modified to reduce the floc breakage and minimise conveyor turbulence in the pool. These features result in considerably reduced dose of polymeric flocculants. In addition there is a substantial economy of space, power and labour required in the operation of the Pennwalt Super-D-Canter Centrifuge in comparison with alternative solid-liquid separations equipment.

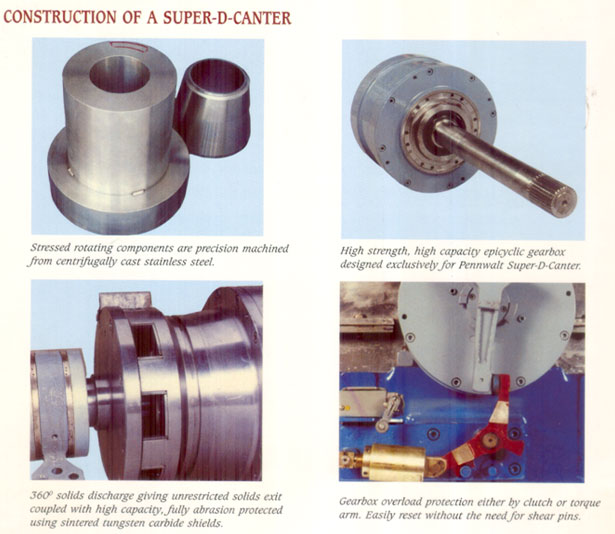

Stainless Steel Construction designed to resist corrosion

Carbon Steel corrodes, leading to unbalance, high maintenance costs, long downtimes. Therefore the principal elements and stressed rotating components of Pennwalt Super-D-Canter Centrifuge are machined from quality centrifugally cast Stainless Steel.

Designed to resist abarsion

Sintered Tungsten Carbide Tiles positioned on the flights of the Pennwalt Super-D-Canter Centrifuge scroll (conveyor) outlast conventional hard surfacing systems many times over in any environment.

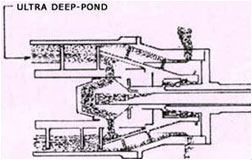

BD Feature

This makes slimy and gelatinous sludges SCROLLABLE. The BD feature allows the Super-D-Canter to operate at Ultra-Deep pond settings that compact the solids and creates hydrodynamic buoyancy that assists the scrolling and the discharge of slimy sludge. The insoluble solid contents are typically 1/2% – 2% in the feed slurry which are thickened to 6%-12% and discharged in the slimy cake.

3-Phase:

The Pennwalt 3 Phase Super-D-Canter centrifuge is designed to separate a feed consisting of two liquid phases and a solid phase into three separate product phases such as water, oil, and cake solids. Applications encompass Olive Oil, Fish Oil, Fish Blood-Water, Slop Oil etc.

Often, one or both liquid phases need to be further polished on the high-G Tubular Bowl Super centrifuge.

Sterile Features

For Pharmaceutical, Biotechnology and Food Industries, the Pennwalt Super-D-Canter Centrifuge can be provided with sterile and Clean-in-Place (CIP) features.

Safety Features

- All electric drives are provided with enclosures of Ingress Protection (IP) ratings selected for safe operation as per process requirements.

- The Pennwalt Super-D-Canter centrifuges are designed and featured for operational safety with Inert Gas (N2) purging to be provided by the end use customer, when operated with feed slurry containing a flammable and/or explosive solids or liquid phase.

Performance

Four crucial factors govern the separational performance of Pennwalt Super-D-Canter centrifuges.

- Centrifugal force required to sediment the solids.

- Appropriate setting of the pool depth to achieve the required centrate liquid clarity.

- Control of differential speed between the bowl and scroll, to convey the solids and obtain appropriately low cake moistures.

- Hydrodynamic design of the conveyor to minimise turbulence.

In specifying a Super-D-Canter centrifuge, for a particular application, Pennwalt also considers other design features such as:

- The pitch of the conveyor flights.

- Number of Leads of the Conveyor.

- Special Rinse or Floc Feature.

- Feed zone design.

- Beach angle.

- Beach Internal Surface Profile.

- Bowl Internal Surface Profile.

- Torque Sensing and Over-load Protection.

- Back drive feature for control of conveyor differential speed.

- Casing Enclosure design.

- Abrasion Protection with Tungsten Carbide Tiles or Stellite Hard Surfacing of the Conveyor.

- Material of construction.

- Sedimentation enhancing features and choice of polyelectrolyte flocculants.

- Safety Featured casing and guards.

The correct combination of such features ensures the desired separational performance with operational safety for a given application at minimum cost. Operation at High ‘G’ force is an inherent design feature of the Pennwalt Super-D-Canter and provides flexibility to the user. The centrifuge can be operated at an optimum speed to suit the particular application. The Pennwalt Super-D-Canter can be operated at low, intermediate or high speed without the constraints of mechanical design, which can be optimised and tailored to suit each application.

Advanages of Pennwalt Super-D-Canter

- Reduces Total disposal volume substantially

- Saves space due to small foot print

- Saves power in comparison with filtration equipment

- Reduces handling costs

- Produces Truckable cake solids discharge

- Totally enclosed casing for odour minimisation and solvent loss minimisation

- Automated Decanter Operation

- Continuous Operation

- Tailored to application specific requirements

Construction of Super-D-Canter

The flexibility of Pennwalt Super-D-Canter Centrifuge design has proved to be effective in evolving solutions to a wide range of solid-liquid separations in the Chemical Process Industry.

However, the ideal methodology of evolving authentically tailored optional solutions to specific Solids-Liquid separational problems is to carry out laboratory settling tests, followed by trials on geometrically similar pilot scale test models of the Pennwalt Super-D-Canter Centrifuge with representative samples of process slurries that need solids-liquid separation. On the basis of the test data obtained, an accurate detailed specification of the scaled-up Super-D-Canter Centrifuge can be recommended to the potential customers.

Representative Samples

The results which are obtained in any pilot scale trials testing program can only be as good as the sample which is tested. Therefore it is absolutely essential that the sample sent to Pennwalt Ltd. for conducting trials is representative in the settling / separational and flocculation characteristics of the process slurry feed to the full-scale on-site Super-D-Canter. A similar consideration applies to the separational characteristics of representative test samples of immiscible liquids and fine solids feed sent for trials with the super centrifuge and to the test samples with representative particle size distribution of solids feed sent for trials on the Vibroscreen, which should match the separational characteristics of process feed that would be fed to the separations equipment in the full-scale plant at site.

Waste water and industrial process applications cover a range of processes found in wide-ranging industries e.g.

| Chemical Process Industry | Mineral Processing Industry |

| Paper processing Industry | Iron & steel industry |

| Vegetable oil-refining | Sugar Industry |

| Water & waste water treatment | Polymer Manufacturing |

| Potato & Root crop processing | Industrial Effluent Treatment |

| Mineral, Fuel, and Lube Oil Process | Mining |

| Foods | Processing | Meat rendering & Fish Processing Industries |

| Bio-Pharmaceutical & Fine chemical | And many more |

| Municipal Effluent Treatment |

Typical Applications of Pennwalt Super D-Canter Centrifuges

| Animal Blood Dewatering | Water Works sludge, Industrial Municipal Waste Treatment Sludges |

| Industrial Effluents | Clarification & Thickening of Primary, Secondary, Digested & Heat Treated Sewage Sludge. |

| Mineral Gypsum | Fish Processing & Dewatering |

| Tannery Effluent | Wine Lees |

| Pharmaceuticals | Whisky spent grain |

| Cutting Oils | Blood Dewatering |

| Mycelium from Fermented Broth | Soya Protein Concentrate |

| Electroplating Solutions | Soya Protein Isolate |

| Fine Chemicals | Brewery Spent Grain |

| Vegetable Oils | Olive Oil |

| Fruit Juices | Flue Gas Desulphurization |

| Food Processing Effluents | Anode Slimes |

| Brewery sludge from Aerobic Effluent Treatment Plant | Di-methyl Terephtallate (DMT) |

| Polymer Dewatering e.g Polystyrene, ABS | Meat Deboning |

| Coal Tailings | Green Liquor recovery |

| Petrochemicals | Phosphoric Acid |

| Distillery Stillage | Polyelectrolyte’s |

| Dyestuffs | By-product Gypsum Removal from Phosphoric Acid |

| Sodium Sulphate | Drilling Mud Separation |

| Ethanol Stillage Dewatering | Manure and Farm Waste Waters |

| Titanium Dioxide | Vegetable Oil Refining (Expellor oils) |

| Brewers Grain | Dewatering Lactose crystals |

| Grape/Mango/Prune/Pear | Starch Dewatering |

| Antibiotics | Paper Mill Effluent / Clarifier Underflows |

| Inedible Tallow | Optimizing sugar mill production by clarification of raw juice, sulphited juice, deliquoring cane mud settlings, dewatering phosphate cane molasses |

| Calcium Carbonate | Dewatering Fruit Juices |

| Chemical Intermediates | Caustic Lye |

| Nuclear Effluents | Ceramic Waste |

| Dairy Effluent | Human Placenta Extract |

| Pigments | Activated and Levigated Clay slurries |

| Enzymes Harvesting | Petrochemical Plant Effluent sludge |

| Fish Liquors | Spent yeast from brewery fermentor |

| Low temperature FAT rendering | Pipe line coal slurry |

| Puree Pulp | And many more |

| Lactose |

Note :

Pennwalt Super-D-Canter centrifuges are compliant with quality requirements of ISO 9001/2008 and with the safety requirements of European EC machinery Directive: 2006/42/EC.

- PM 20000 is the Polymiser version of Model P-3000 Super-D-Canter.

- PM 30000 is the Polymiser version of Model P-3400 Super-D-Canter.

- Gearbox reduction ratios are selected as per process specific requirements.

- Material of construction of the process contact parts and the rotating bowl is S.S 316. However this can be re-considered on application specific basis as per end-user requirements.